How Does Steam Distillation Work?

Process

Mother Nature produces water through the natural cycle of evaporation, precipitation and condensation. The sun heats bodies of water upon the earth and evaporates into the sky to be captured in clouds. The clouds are then cooled, releasing the water. As it leaves the clouds, this precipitation is pure. As it makes its descent, the water picks up various forms of pollution found in the air. Once the water reaches the ground, it continues to pick up contaminants as it makes its way back to bodies of water.

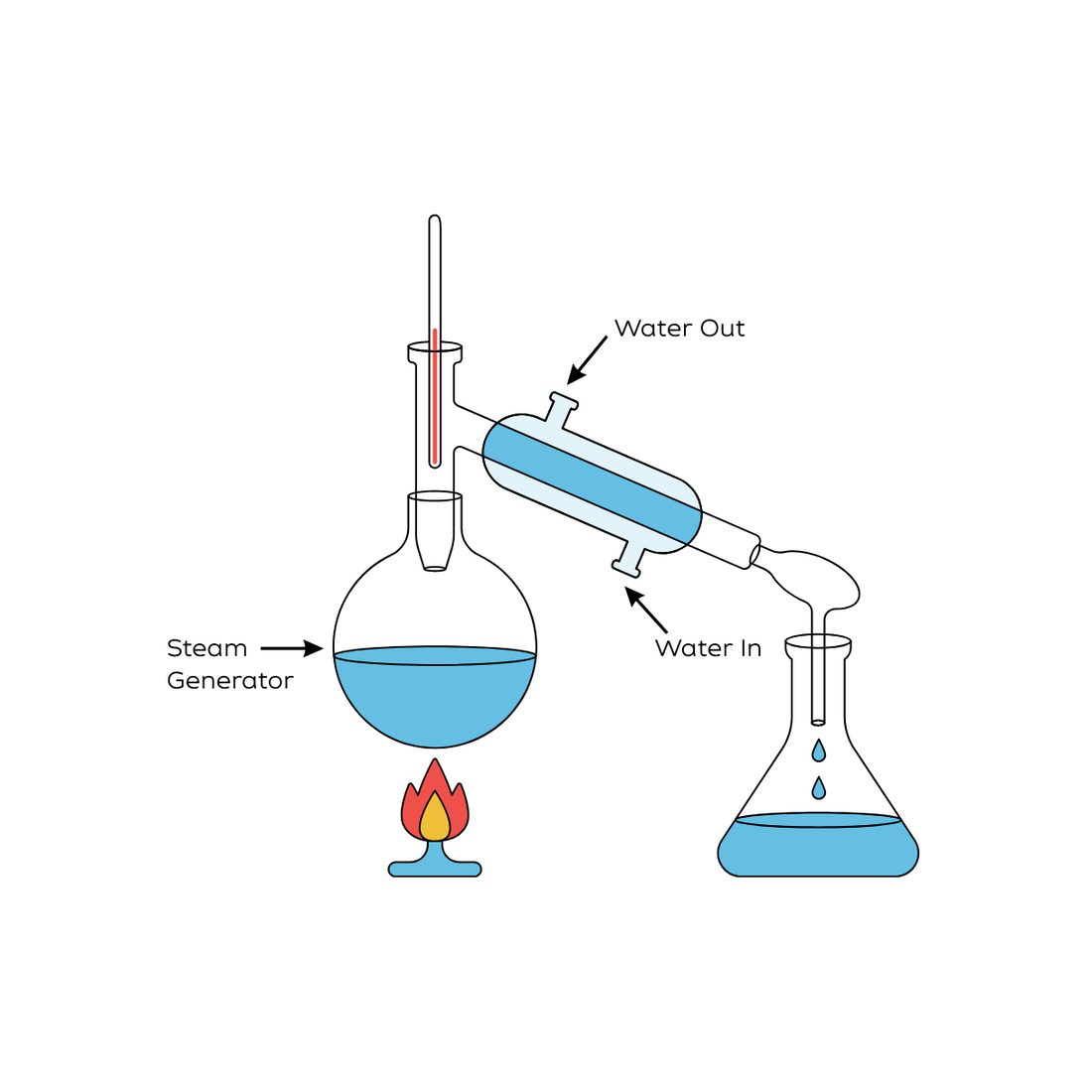

Distillation duplicates the original process of Mother Nature. Distillation begins by boiling the water. As hot vapor rises, it is captured in a baffle and enters cooling coils. A fan cools the hot vapor into condensed, pure water.

The distillation process is a human-controlled version of the hydrological cycle. Distillation uses the process of evaporation; cooling and condensation to separate water molecules from unwanted substances and contaminants. The process of boiling kills any bacteria or viruses present in the water. Everything is left behind in a boiling tank to be discarded down the drain.

History

Over 2,000 years ago, ancient Greek sailors used a form of distillation at sea. They would hang sponges over pots of boiling water, squeezing out the precious water condensed in the sponges from the steam. Although derived from seawater, this sponge water was no longer salty and was safe to drink.

Effectiveness

The first residential water distiller was designed primarily to remove dissolved solids and inorganic salts. As more sophisticated chemicals were created by humankind, the need evolved for further advancements in distillation equipment.

Many distillers today utilize a volatile gas vent, which consists of a pinhole in the top of the condensing coils to vent off unwanted gasses. If any gasses happen to escape, they are collected in a carbon post-filter. These charcoal filters provide double assurance that these gasses will not end up in the distilled water storage tank, and do not breed bacteria as only pure water runs through them.

Some systems have a proven rejection rate of greater than 99% of all contaminants. There is no other process as efficient or as reliable. Water distillation can remove many contaminants, such as chlorine, nitrates, fluoride, ammonia, aluminium, arsenic, copper, iron, mercury, radium, asbestos, viruses, bacteria, herbicides and pesticides - to name a few.

Reliability

Most distillers do not require the constant monitoring that other treatment methods do. Since the distillation process is so simple, very little can go wrong, Customers that understand the process are able to trust it and have peace of mind in the system's operation.

Quality distillation systems are constructed of high-grade stainless steel. Built to last a lifetime, a distiller should consistently deliver the same quality of pure drinking water over the years, with few or no service problems.

Distiller maintenance consists of draining out leftover residue from the boiling process and changing the charcoal filters every 6-12 months. If a heavy scale build-up accumulates in the boiling tank, a cleaning agent is required to soften and loosen up the scale.

Some distillers offer low-maintenance, self-flushing options to reduce maintenance requirements.

Advantages

Distillation has many benefits over other treatment methods:

- Easily and efficiently removes toxic chemicals, bacteria/viruses, and inorganic minerals.

- Units are tailored to residential and commercial use.

- Distilled water has many health benefits!

- There are many uses for distilled water - anything from baby formula to watering houseplants to cooking.

Residential Use

There are essentially two types of water distillers available for residential use. Water-cooled models require 5-15 gallons of tap water to make 1 gallon of distilled water. Although quieter to run, they require a drain close by for the hot water. Air-cooled versions tend to be more popular because they do not waste excess water and produce one gallon of pure water per approximately one gallon of feed water.

Distillers may be countertop/portable manual units, semi-automatic, or fully automatic. Popular locations for these units are basements and laundry rooms. Most may be connected to a pressurized system, allowing pure water to run to separate faucets in the home. Lines may be run to the furnace humidifier (saving frequent cleaning due to mineral buildup) and refrigerator icemakers. Dispensing systems and water coolers can also be connected into distilled water lines!

Overall, distillation is highly efficient, reliable, readily available and crucial to the pursuit of good health. If it has been a while since you considered distillation, or if it's the first time you're hearing of it - now is the time to make the commitment!